Jiangsu Youcann Intelligent Equipment Co., Ltd.

PHONE:

PHONE:

0516-83050599

15952206522

consult:

consult:

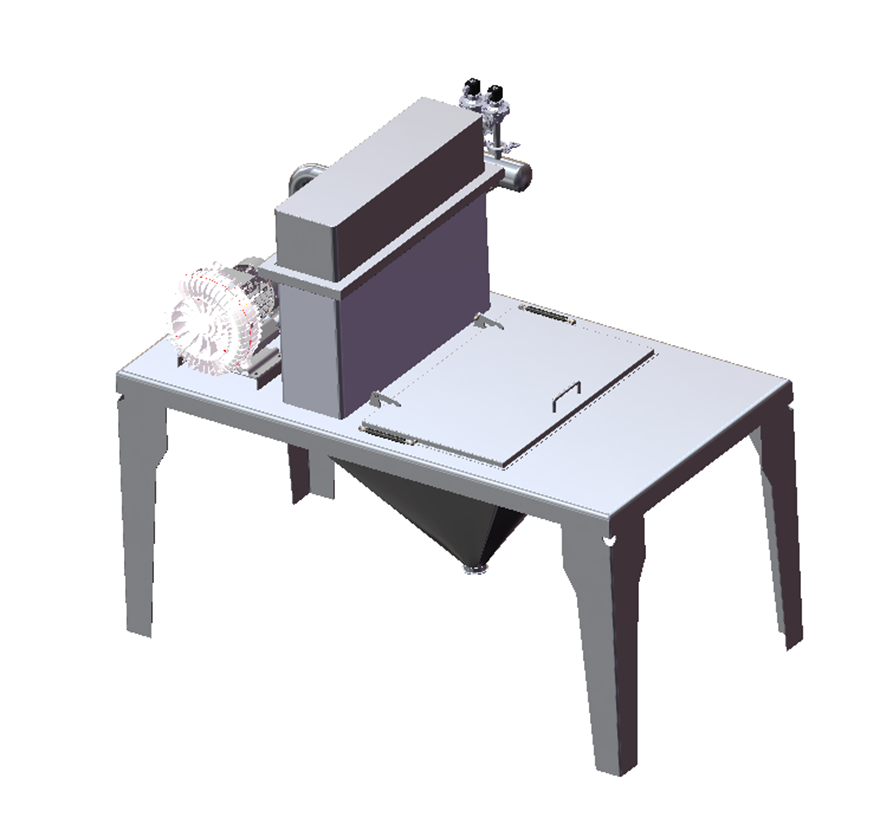

Uniconn's dust-free feeding station is suitable for feeding production in the production of industrial chemicals and mixtures such as food, beverages, dairy products, pharmaceuticals, and condiments. The dust-free feeding station is mainly composed of a feeding platform, a feeding bin, and a dust removal and separation system. The feeding equipment used to dump powder or granular materials to the downstream production line. It can make the materials fall into the storage hopper by gravity through steps such as manual bag unpacking or automatic bag cutting and dumping to complete the feeding work. The dust-free feeding station can solve the problem of dust flying during the production and feeding process, avoid dust pollution, etc., and meet the requirements of easy observation, easy operation, easy cleaning and GMP compliance.

Material and supporting instructions: The feeding station is equipped with a safety door lock to prevent manual opening. It can be opened only after the system is started. At the same time, there is a gas spring on the feeding station cover to assist in opening the door cover and prevent the door cover from closing during operation. There is a proximity switch on the cover, and the dust removal fan automatically turns on when the door cover is opened to ensure that the dust does not rise. Put the materials into the feeding station. The feeding station uses the top dust collection system to reduce the phenomenon of dust flying during feeding, and protect the health and safety of workers and the operating environment. After working for a period of time, the back-blowing system starts to blow the dust on the filter cloth bag into the feeding hopper.