Jiangsu Youcann Intelligent Equipment Co., Ltd.

PHONE:

PHONE:

0516-83050599

15952206522

consult:

consult:

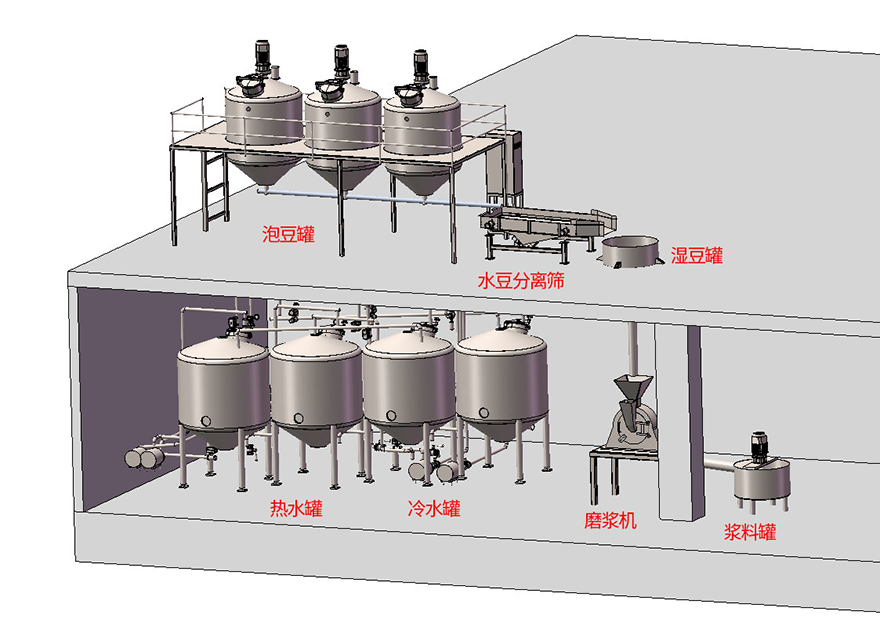

The automatic soaking system can be used in the pre-processing production lines of soy milk powder, soy milk, and soy products. Uniconn can customize fully automatic automatic washing and soaking system for customers. The system can realize fully automatic control, without manual operations such as automatic metering of soybeans, quantitative water addition, automatic drainage, and bean discharge.

The bean soaking system is equipped with a negative pressure tank for soaking beans. When the soaking tank reaches the set value of negative pressure, the watercress in the metering tank is directly sucked into the inverted bean tank through the negative pressure pipe, and the soda water is first rinsed after the suction is completed. , The purpose is to remove the smell of soybeans, dust and impurities. After starting the stirring, it will achieve rapid washing. After the washing is completed, drain the water. After the drain is completed, enter the 85-90 degree hot water to soak the beans. Start the stirring and soak the beans evenly. After a certain period of time, the hot water is drained and enters the cold water to cool down. After cooling, the watercress is discharged through the pipe. The water and the watercress are separated at the vibrating screen, and the watercress enters the semi-finished product tank, and the water is separated and discharged. According to the soaking process, all valves and pumps are controlled by PLC program, and all tank temperature, liquid level, pressure, weighing and other sensors are monitored in real time, which completely solves the loss caused by human error.